Leave Your Message

Comprehensive analysis of inflatable Dock shelter

Introduction

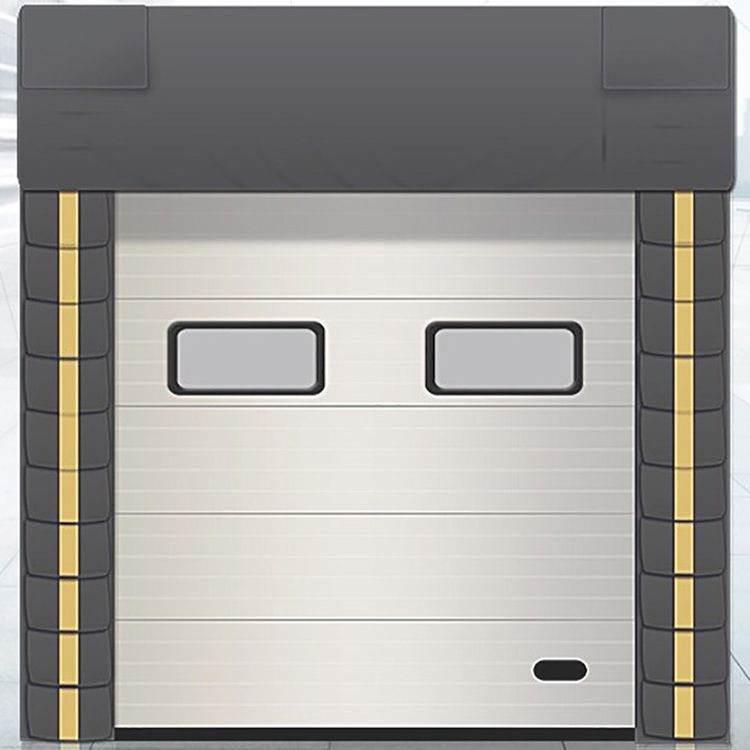

In modern industry, the efficiency of logistics and transportation is crucial to business operations. In order to ensure the smooth flow of goods and protect valuable goods from adverse environmental effects, the technology of the industrial door control industry continues to innovate. Among them, Inflatable Dock Shelter, as a key technology, has become an indispensable equipment to ensure logistics operations and warehousing environment.

The function of inflatable Dock shelter:

The inflatable Dock shelter is a high-tech door control device. Its main function is to effectively isolate the indoor and outdoor environments and provide sealing performance during the process of loading and unloading goods. Its unique design uses inflatable technology to quickly adapt to changing dimensions as cargo moves in and out, creating an effective isolation barrier. This technology not only helps maintain indoor temperatures but also effectively protects against dust, wind, rain, and other adverse weather elements.

Importance in industry:

In modern industrial production, especially in the fields of logistics, warehousing and transportation, inflatable Dock shelter plays a vital role. Its importance is mainly reflected in the following aspects:

Environmental protection: inflatable Dock shelters can effectively isolate the indoor and outdoor environments and prevent dust, debris, and pollutants from entering the warehouse, thereby ensuring that the stored goods maintain good quality and hygiene standards.

Energy efficiency: By reducing the temperature difference between indoors and outdoors, inflatable Dock shelters help reduce energy consumption and improve overall energy efficiency, especially in harsh climate environments.

Improved work efficiency: inflatable Dock shelters can quickly adapt to transportation vehicles of different sizes, improve the efficiency of loading and unloading goods, reduce transportation pause time, and help optimize logistics operations.

Cargo protection: By providing reliable sealing performance, the inflatable Dock shelter protects cargo from weather, dust and other external factors, reducing the risk of cargo damage.

In this era of continuous pursuit of efficiency and environmental protection, inflatable Dock shelters are gradually becoming key equipment in the modern industrial door control industry with their excellent performance, providing enterprises with more reliable and efficient logistics solutions. Next, we will delve into the material selection, installation steps, price comparison, etc. of inflatable Dock shelters to provide you with a comprehensive analysis of the essence of this door control technology.

Inflatable Dock shelter material selection guide

Analyze the properties of different materials:

Wear resistance:

Polyester fiber (Polyester): It has strong wear resistance, is suitable for high-frequency use environments, and can withstand the friction that may be caused when goods are put in and out.

Polyurethane Coating: Provides additional wear-resistant protection and enhances the life of the Dock shelter, especially suitable for scenarios where cargo is frequently loaded and unloaded.

Weather resistance:

Polyurethane Coating: It has excellent weather resistance and can withstand extreme weather conditions such as ultraviolet rays, high temperature, and low temperature, ensuring that the Dock shelter maintains good performance in various climate environments.

Polyvinyl Chloride (PVC): Has some weather resistance, but may be slightly more brittle in extreme weather conditions than polyurethane coatings.

Sealing:

Polyurethane Foam: As a filler for the sealing layer, polyurethane foam has excellent sealing properties and can effectively fill the gap between the Dock shelter and the transport vehicle to improve the sealing effect.

Rubber Seals: Some Dock shelters use rubber seals, whose softness and pressure resistance ensure stable sealing performance.

The importance of choosing inflatable Dock shelter materials:

Ensure durability: The choice of different materials directly affects the service life of the inflatable Dock shelter. Materials with strong wear resistance can withstand wear and tear caused by frequent use, while materials with good weather resistance ensure the stable operation of the Dock shelter in various climate conditions.

Ensure the sealing effect: One of the main functions of the inflatable Dock shelter is to provide a reliable sealing effect and prevent indoor and outdoor air exchange from affecting the storage environment. Choosing materials with superior sealing properties, such as polyurethane foam and rubber sealing strips, is crucial to maintaining a good seal.

Adapt to diverse environments: The industrial environment is ever-changing, from high temperatures to severe cold. Different materials can ensure that the inflatable Dock shelter remains stable and reliable under various extreme conditions. Especially in the logistics industry, Dock shelters need to adapt to various vehicles and environments.

Maintenance cost and efficiency: Wear-resistant and weather-resistant materials generally have lower maintenance costs while ensuring long-term stable operation of the Dock shelter, helping to improve work efficiency and reduce downtime and repair time.

Taking these factors into consideration, enterprises should fully understand the characteristics of different materials when selecting inflatable Dock shelter materials, and select the most suitable Dock shelter materials based on specific application scenarios and needs to ensure that the Dock shelters perform best in the industrial environment.

When selecting inflatable Dock shelter materials, multiple factors need to be considered to ensure that the Dock shelter can provide the best performance and effect in different environments. Here are some suggestions to help you make an informed choice:

Understand the application environment: Fully understand the environment in which the Dock shelter will be used, including temperature range, climatic conditions, and frequency of use. Choose materials whose wear resistance, weather resistance, and sealing properties better meet your needs according to the specific situation.

Consider the frequency of the Dock shelter: If the Dock shelter is used frequently, choose materials with higher wear resistance, such as polyester fiber and polyurethane coating, to ensure that it is not prone to wear and tear during long-term use.

Pay attention to sealing: One of the main functions of Dock shelters is to provide effective sealing performance. Choose materials with excellent sealing properties, such as rubber sealing strips or polyurethane foam, to ensure that the Dock shelter can effectively prevent the penetration of air and dust when in use.

Focus on weather resistance: If the Dock shelter is exposed to different climate conditions, choose a material with good weather resistance, such as a polyurethane coating. This helps the Dock shelter remain stable under high or low temperatures or when exposed to intense UV rays.

Maintenance Cost Considerations: Consider the maintenance costs and durability of materials. Some materials may require more frequent maintenance, while some materials with lower maintenance costs and long life may be better suited for long-term investments.

Understand industry standards: Understand the standards and specifications of the industrial door control industry and ensure that the materials selected meet relevant industry requirements and safety standards.

Work with suppliers: Work with reliable suppliers for professional advice and recommendations. Suppliers usually have extensive experience and can provide customized solutions based on your specific needs.

Reference cases and customer feedback: Check out relevant cases and customer feedback to understand the performance of different materials in practical applications. This allows for a more complete assessment of the strengths and weaknesses of the material.

By comprehensively considering these factors, companies can more accurately select the inflatable Dock shelter material that suits their needs to ensure that the Dock shelter can provide the best effect and performance in actual use.

Detailed explanation of the installation steps of inflatable Dock shelter

An in-depth discussion of the steps to install an inflatable Dock shelter:

Check before preparation:

Before installing an inflatable Dock shelter, make sure the loading and unloading area of the warehouse or logistics center is clear of obstructions.

Check the wall and door frame to ensure that the surface is smooth and has no obvious damage to ensure the firmness of the Dock shelter installation.

Frame installation:

Install the Dock shelter frame, ensuring that the frame is vertical and level. Use a level and measuring tools to adjust the frame to ensure its stability and accuracy.

Power and control system connections:

Connect the inflatable Dock shelter's power cord and control system to a stable power source. Make sure cables and wiring connections are secure to avoid electrical problems affecting the operation of the inflatable Dock shelter.

Install the inflatable bag:

Secure the inflatable bag to the Dock shelter frame, making sure the bag is positioned accurately and does not overlap or cross. Adjust the position of the bag to fit different sizes of transport vehicles.

Connect the inflation bag to the control system:

Connect the inflatable bag to the control system to ensure that the inflatable bag can expand and contract as needed. Adjust control system parameters to suit specific logistics needs.

Test the inflation effect:

Before actual use, test the inflatable Dock shelter. Observe whether the inflatable bag can be fully expanded and completely sealed with the transport vehicle to ensure a good sealing effect.

Adjustment and calibration:

Adjust the tension and position of the inflatable bag according to the actual situation to ensure the best sealing effect when various transport vehicles enter and exit.

Calibrate the control system to ensure it accurately responds to various instructions and ensure the normal operation of the inflatable Dock shelter.

Training operators:

Provide training on the normal operation and maintenance of Dock shelters to ensure that operators understand how to use Dock shelters and possible problem-solving methods.

Regular maintenance:

Establish a regular maintenance plan, including cleaning the surface of the inflatable bag, checking the power supply and control system, tightening screws, etc. This helps extend the life and performance of your inflatable Dock shelter.

Security check:

Conduct safety checks to ensure Dock shelters are installed in a manner that will not affect the safety of surrounding workers and equipment. Mark the emergency stop button and safety signs to ensure that the operation of the inflatable Dock shelter can be quickly stopped in an emergency.

By following these installation steps step by step, with special attention to detail and precision, you can ensure that the inflatable Dock shelter will provide the best results in actual use while reducing the need for maintenance and repairs and ensuring smooth logistics operations.

Emphasizing the key factors of proper installation of inflatable Dock shelters is a critical step in ensuring optimal Dock shelter effectiveness. Here are some important considerations:

Clean surfaces: Before installing the inflatable Dock shelter, make sure the door frame and door surfaces are clean. Remove any dust, grease, or other dirt to ensure the Dock shelter seals completely.

Measurements: Before purchasing a Dock shelter, accurately measure the dimensions of your door frame. Choose a Dock shelter that matches the dimensions of your door frame to ensure a perfect fit and provide the best possible seal.

Proper installation position: Make sure the Dock shelter is installed in the correct position. Generally speaking, the Dock shelter should be installed around the door frame, ensuring that it fits perfectly around the edge of the door.

Correct inflation pressure: Inflatable Dock shelters usually require the use of an air pump for inflation. Make sure to use the proper inflation pressure and follow the instructions provided by the manufacturer. Too high or too low inflation pressure may affect the sealing effect.

Check for air leaks: After installation, carefully check all parts of the Dock shelter, especially the connections, to make sure there are no air leaks. Fix any issues that may cause gas leaks to maintain the best possible seal.

Regular Inspection and Maintenance: Dock shelters may become worn or damaged during use. Regularly check the condition of the Dock shelter and promptly repair or replace any damaged parts to ensure continued effectiveness.

By carefully following the steps above, you can ensure that your inflatable Dock shelter is installed correctly and provides the best possible seal, preventing air, moisture, or other outside materials from entering the home.

When installing an inflatable Dock shelter, here are some practical tips and considerations to ensure a smooth and effective installation:

Prepare your tools: Before you begin the installation, make sure you have the tools you need, such as an air pump, measuring tools, cleaning supplies, and possibly a screwdriver or screw wrench.

Pre-measure and prepare: Before purchasing a Dock shelter, measure the height and width of your door frame to ensure you choose the right size Dock shelter. Before installation, make sure the surface of the door frame is clean and remove any obstructions that may affect the seal.

Keep the door frame plumb and level: When installing the Dock shelter, make sure the door frame is plumb and level. This helps ensure that the Dock shelter fits evenly and avoids air leakage problems caused by irregular door frames.

Correct inflation pressure: When using an air pump, make sure it is set to the correct inflation pressure according to the manufacturer's recommendations. Too high pressure may cause damage to the Dock shelter, while too low pressure may affect the sealing effect.

Gradual inflation: When inflating the Dock shelter, proceed step by step and check the sealing effect regularly. This ensures that the Dock shelter inflates evenly and avoids excess air pressure in certain areas.

Check for air leaks: After installation, carefully inspect each connection point and edge of the Dock shelter to look for potential air leaks. If air leakage is found, repair it promptly, such as readjusting the inflation pressure or replacing damaged parts.

Regular Inspections and Maintenance: Dock shelters require regular inspections to ensure their long-term effectiveness. Check whether the Dock shelter is damaged or foreign matter is attached, and take necessary maintenance measures.

Follow the manufacturer's guidelines: Most importantly, always follow the installation guidelines provided by the manufacturer. These guides contain product-specific details to ensure proper installation and use.

By being careful and following the tips and precautions above during installation, you can ensure that your inflatable Dock shelter will work optimally in actual use, providing effective sealing and isolation.

Inflatable Dock shelter and environmental isolation effect

An inflatable Dock shelter is a common isolation device found in industrial environments. It is often used to seal off two areas to prevent gases, liquids, dust, or other environmental elements from passing through. The isolation effectiveness of an inflatable Dock shelter depends on several factors. Here are some key factors that may affect its performance:

Material selection: Inflatable Dock shelters are usually made of rubber or other elastic materials. The quality and characteristics of the material directly affect the effectiveness of the seal. Materials that are resistant to wear, chemicals, and temperatures are generally more suitable for industrial environments.

Closing pressure: The closing effect of the inflatable Dock shelter is related to the inflation pressure. Proper inflation pressure ensures that the Dock shelter seals well without causing over-expansion or damage.

Dock shelter Design: The design of the Dock shelter is critical to its performance. The design including the shape, size, and connection method of the Dock shelter will affect its isolation effect in the industrial environment.

Installation quality: The correct installation of the inflatable Dock shelter is also a key factor in ensuring its effectiveness. Make sure the Dock shelter is installed correctly and does not have any damage or leaking points.

Environmental conditions: Various conditions may exist in industrial environments, such as high temperature, high humidity, chemicals, etc. Inflatable Dock shelters need to be adapted to these conditions or their performance may be affected.

Maintenance and Inspections: Regular maintenance and inspections are important steps to ensure the long-term effectiveness of your inflatable Dock shelter. Check regularly for possible wear, damage, or leaks and repair them promptly.

Overall, the isolation effectiveness of inflatable Dock shelters in industrial environments depends on a combination of factors. During the selection, installation, and use process, the above factors should be paid attention to ensure that the Dock shelter works best in the industrial environment.

The isolation effect of inflatable Dock shelters in industrial environments is mainly reflected in their dustproof, windproof, and moistureproof properties. These characteristics play an important role in maintaining the cleanliness, safety, and stability of the production environment.

Dustproof effect:

The inflatable Dock shelter forms a sealed isolation through inflation, effectively preventing dust, particles, and other tiny particles from entering the work area. This is particularly critical for some industrial environments with high requirements for cleanliness, such as electronic manufacturing, food processing, etc., which can improve production efficiency, reduce equipment failure rates, and ensure product quality.

Windproof effect:

In high wind speed environments, the inflatable Dock shelter can quickly inflate and form an effective closing barrier to block the intrusion of external wind. This helps maintain normal production order and improve work efficiency for outdoor industrial sites or situations where airflow needs to be prevented from hurting production lines, such as aerospace manufacturing, automobile manufacturing, etc.

Moisture-proof effect:

In some humid environments or industrial situations where relative humidity needs to be maintained, the sealing effect of the inflatable Dock shelter helps prevent moisture intrusion. This is of great significance for protecting equipment from corrosion, extending equipment life, and maintaining the stability and reliability of the production line.

Overall, the role of inflatable Dock shelters in preventing dust, wind, and moisture helps to improve the hygiene standards, production efficiency, and equipment reliability of industrial environments. When selecting and using, specific industrial needs and environmental conditions need to be considered to ensure that the inflatable Dock shelter can meet the corresponding isolation requirements.

The effects of Dock shelters under different environmental conditions also vary.

Electronic manufacturing industry:

In electronics manufacturing workshops, the requirements for cleanliness are extremely high. Inflatable Dock shelters can effectively isolate external air, prevent impurities such as dust and fine dust from entering the production line, and ensure a clean production environment for electronic products. This helps improve production efficiency, reduce defect rates in the manufacturing process, and improve product quality.

Food processing plants:

In food processing plants, inflatable Dock shelters can be used in freezers, fresh-keeping warehouses, and other environments to prevent the loss of cold air, while preventing external air, dust, impurities, and other pollutants from entering the food processing area to ensure food hygiene and safety standards.

Automobile factory:

In automobile manufacturing workshops, inflatable Dock shelters can be used in the body painting process. The sealing effect can effectively prevent external wind from entering the painting area, ensuring the quality of the painting and reducing the scrap rate. At the same time, the dust-proof effect helps keep the painting environment clean and improves the surface quality of the car body.

Warehousing and logistics center:

In large warehousing and logistics centers, inflatable Dock shelters can be used in cargo loading and unloading areas. Forming an effective seal to prevent external airflow, dust, and moisture from entering the warehouse, helps maintain the quality of goods and reduce inventory losses.

Pharmaceutical industry:

In pharmaceutical factories, inflatable Dock shelters can be used in clean rooms, laboratories, and other areas. Dust-proof and moisture-proof effects are crucial to the cleanliness and stability of pharmaceutical production, ensuring that the production process is not contaminated by the external environment.

These examples highlight the versatile role of inflatable Dock shelters in different industrial environments, improving production efficiency, and product quality, and ensuring hygiene and safety in work areas by isolating external factors. In practical applications, appropriate inflatable Dock shelter types and specifications need to be selected based on specific production requirements and environmental conditions.

Customized inflatable Dock shelter solutions

Advantages of customized Dock shelters

Customized Dock shelters offer many advantages in industrial and commercial applications, including:

Adaptability and flexibility:

Customized Dock shelters can be designed and manufactured according to the customer's specific needs and environmental requirements, making them extremely flexible. Whether it is for special shapes, sizes, or special industrial environment needs, customized Dock shelters can provide better adaptability and ensure the best performance and effect.

Precise isolation effect:

Customized Dock shelters can be precisely designed to meet specific isolation needs, such as dust, wind, moisture, etc. Through targeted design, Dock shelters can be ensured to provide optimal isolation in specific environments, thereby better-protecting equipment, goods, or production processes.

Improve efficiency and production quality:

Because customized Dock shelters can be optimized according to production processes and equipment characteristics, production efficiency can be improved. Customized design ensures perfect cooperation between Dock shelters and equipment, reduces unnecessary energy waste, reduces production line failure rates, and ultimately improves product quality.

Comply with special environmental requirements:

Some industries and industrial environments have special requirements for Dock shelters, such as high temperatures, low temperatures, chemical exposure, etc. Customization allows the selection of suitable materials and technologies to ensure the long-term durability and performance of Dock shelters in specific environments.

Personalized design:

Customized Dock shelters can be personalized according to the customer's brand image, color, and design needs. Not only does this enhance the professional image of the business, but it also meets customer expectations for appearance and brand consistency.

Ease of maintenance and service:

Customized Dock shelters are designed with ease of maintenance and service in mind, including features such as ease of cleaning and ease of repair. This helps reduce maintenance costs and improves the overall serviceability of the Dock shelter.

In general, the advantages of customized Dock shelters lie in their flexibility, customization, adaptability, and accuracy, which can better meet the specific needs of customers and improve the efficiency and performance of Dock shelters in industrial and commercial applications.

Customized solution process and steps

The process and steps of customized Dock sheltering solutions can be divided into the following stages:

demand analysis:

Determine the customer's specific needs, including isolation effectiveness, size, material requirements, industrial environment characteristics, etc. Understand the customer's application scenarios to better meet the functional and performance requirements of customized Dock shelters.

design phase:

Develop a preliminary design plan, including the structure, materials, sealing methods of the Dock shelter, etc. Customized design of structure and function based on customer needs and environmental characteristics. Work closely with clients to ensure designs meet their expectations.

Sample making:

Produce prototypes or samples to verify design feasibility and meet customer expectations. Through feedback with the client, necessary modifications and adjustments are made until a final confirmed design is obtained.

material selection:

Choose the appropriate material according to the use environment and requirements of the Dock shelter. This may include special waterproof, dustproof, fireproof, or heat-resistant materials to ensure that the Dock shelter operates stably in a variety of conditions.

Production and manufacturing:

Carry out preparations before mass production and ensure that all materials and production equipment are available. Start manufacturing customized Dock shelters and conduct strict quality control during the production process to ensure that the product meets the design specifications and customer requirements.

Testing and verification:

Conduct comprehensive testing on customized Dock shelters, including verification of isolation effect, durability, performance stability, etc. Ensure that products can operate normally under various working conditions and meet design standards.

Delivery and installation:

Customized Dock shelters are delivered to the customer and installation services are provided where required. Make sure the Dock shelter is installed correctly and functions as expected in the actual application.

After-sales service:

Provide after-sales service and support, including maintenance, repair, and technical support. Establish long-term cooperative relationships with customers to ensure their product satisfaction and experience.

The above process and steps can be adjusted according to the specific customized Dock shelter project and customer needs. It is important to maintain close communication with the client to ensure that the customized solution fully meets their needs and to maintain a high level of quality control throughout the process.

The applicability and flexibility of custom Dock shelters

Customized Dock shelters have strong applicability and flexibility, which are mainly reflected in the following aspects:

Meet specific needs:

Customized Dock shelters can be designed and manufactured according to customer-specific needs, including size, shape, function, material, and other requirements. This allows customized Dock shelters to fully adapt to the needs of different industries, environments, and application scenarios, thereby meeting various special needs.

Adapt to different environments:

Since customized Dock shelters can be made of specific materials, they can adapt to various environmental conditions, such as high and low temperatures, humidity, corrosive environments, etc. This adaptability makes custom Dock shelters stable and reliable in both industrial and commercial environments.

Flexible design and structure:

The design and structure of custom Dock shelters can be adapted to specific application scenarios. For example, different sealing methods, door structures, or air chamber shapes can be designed to ensure optimal performance and isolation. This flexibility allows custom Dock shelters to be adapted to different process flows and equipment layouts.

Personalized look and brand image:

Customized Dock shelters can be designed according to the customer's brand image and personalized needs, including color, logo, shape, etc. This helps to enhance the corporate image and makes the Dock shelter not only a functional device but also has brand recognition.

Versatility:

Customized Dock shelters can integrate multiple functions, such as dustproof, windproof, waterproof, fireproof, etc. This versatility allows Dock shelters to play a wider role in different industrial environments while meeting diverse needs.

Quick response and adjustment:

Because custom Dock shelters are usually manufactured on demand, the production cycle is short and they can respond quickly to customer needs. During the production process, if adjustments or modifications are needed, they are relatively easy to implement, ensuring that the final product fully meets customer expectations.

Taken together, the applicability and flexibility of customized Dock shelters make them an ideal choice to adapt to diverse needs and can provide highly personalized Dock shelter solutions for different industries and enterprises.

Inflatable Dock shelter maintenance and care recommendations

Regular maintenance of Dock shelters is essential to ensure their normal operation and extend their service life. Here are some suggestions highlighting the need for regular maintenance and describing possible maintenance problems and solutions:

Clean the Dock shelter surface:

Problem: Accumulation of dust, oil, or other debris on the surface may affect sealing effectiveness.

Solution: Clean the surface of the Dock shelter regularly and use a mild detergent to ensure that the surface of the Dock shelter remains clean to avoid impurities affecting the sealing performance.

Check the air chamber and sealing strip:

Problem: Air chamber leaks or damaged seals may result in reduced isolation effectiveness.

Solution: Regularly check whether the air chamber is properly inflated and check the integrity of the sealing strip. If there is any problem, replace or repair it in time.

Lubricate moving parts:

Problem: The sliding parts of the Dock shelter such as tracks and wheels may wear due to friction.

Solution: Lubricate moving parts regularly and use appropriate lubricating oil or grease to ensure smooth opening and closing operation of the Dock shelter and reduce wear.

Check electrical components:

Problem: Electrical components such as sensors and control systems may be faulty.

Solution: Regularly check the connection of electrical components to ensure that the sensor is working properly and the control system is stable. If there is a fault, repair or replace it in time.

Prevent the accumulation of foreign matter:

Problem: Debris may accumulate in the area near the Dock shelter, which affects the normal operation of the Dock shelter.

Solution: Clean the area around the Dock shelter regularly to ensure that no obstacles or debris affect the movement and operation of the Dock shelter.

Check the air chamber inflation system:

Problem: The air chamber inflation system may have an air leak or unstable pressure.

Solution: Regularly check the air chamber inflation system, repair air leakage points, and ensure that the air chamber is inflated normally and maintains stable pressure.

Regular maintenance records:

Problem: Neglecting to perform regular Dock shelter maintenance can lead to potential problems being overlooked.

Solution: Record the regular maintenance of the Dock shelter, including maintenance time, maintenance content, etc., which will help to detect potential problems in time and take corresponding maintenance measures.

Through regular maintenance and upkeep, the normal operation of the Dock shelter can be ensured and the possibility of failure can be reduced, thereby extending the service life of the Dock shelter and improving its reliability and performance.

Application of inflatable Dock shelters in logistics industry

Inflatable Dock shelters are widely used in the logistics industry, mainly because of their good isolation effect, ability to withstand a variety of environmental conditions, and the ability to improve logistics efficiency. The following are some key points regarding the wide application of inflatable Dock shelters in the logistics industry:

Maintain cargo quality:

Inflatable Dock shelters play an isolation role during cargo transportation, effectively preventing external pollutants, dust, moisture, etc. from entering the truck or warehouse. This helps maintain the cleanliness and quality of goods, especially for items that require a clean environment, such as food, medicine, etc.

temperature control:

When transporting temperature-sensitive goods, inflatable Dock shelters form an effective barrier in trucks or warehouses, helping to maintain the right temperature. This is of great significance for cold chain logistics, food, pharmaceutical, and other industries, especially under changing climate conditions.

Improve energy efficiency:

The insulating effect of inflatable Dock shelters helps reduce temperature differences between the inside and outside of a truck or warehouse, thereby reducing energy consumption. This has a positive impact on improving energy efficiency, reducing energy waste, and reducing transportation costs.

Fast, automated operation:

Inflatable Dock shelters usually have the characteristics of rapid opening and closing, and some can even be operated automatically. This helps improve the loading and unloading efficiency of trucks, reduces transportation time, and improves the operational efficiency of the entire logistics chain.

Prevent cargo damage:

Inflatable Dock shelters reduce the impact of external wind on goods through effective sealing and isolation and help prevent goods from being damaged by wind, rain, and other weather factors during transportation.

Improve security:

Inflatable Dock shelters can add security to your truck or warehouse, preventing break-ins, theft, and other security issues. They can often be integrated with security systems to provide additional security.

Adapt to different cargo sizes:

The design of the inflatable Dock shelter is relatively flexible and can be adjusted according to different sizes of cargo. This makes them suitable for a variety of different-sized van and warehouse doors.

Taken together, the wide application of inflatable Dock shelters in the logistics industry not only improves the quality and safety of goods but also helps improve logistics efficiency and reduce energy consumption, thus playing an important role in the entire supply chain.

Inflatable Dock shelters are widely used in the logistics industry and play an important role in improving logistics efficiency, enhancing cargo safety, and controlling operating costs. The following are the key roles of inflatable Dock shelters in the logistics field:

Logistics efficiency improvement:

Inflatable Dock shelters can form effective airtight isolation to prevent external air, dust, insects, and other substances from entering the cargo storage and transportation area. This helps to maintain the cleanliness and quality of goods, reduce losses, and improve overall logistics efficiency.

Temperature control and maintenance:

In logistics environments where temperature control is required, inflatable Dock shelters can effectively block heat loss or the influence of external temperature. This is crucial for cold chain logistics, food storage and transportation, and other fields to ensure that goods are transported under suitable temperature conditions and maintain the freshness and quality of products.

Dust-proof, moisture-proof, and insect-proof:

The sealing effect of the inflatable Dock shelter can prevent dust, moisture, and pests from entering the storage and transportation area, reducing the risk of goods being affected by the environment. This helps maintain the hygienic condition of goods, reduces loss and contamination of goods, and improves the tidiness of the logistics process.

Enhanced cargo security:

As part of logistics equipment, inflatable Dock shelters can enhance the safety of goods. Through effective sealing, illegal acts such as theft and vandalism are prevented, and the safety of goods during transportation is improved.

Reduce energy consumption:

Inflatable Dock shelters can reduce airflow inside and outside the cargo storage area and reduce energy loss. This can reduce energy consumption and improve energy efficiency for storage and transportation environments that require temperature control.

Reduce maintenance costs:

Inflatable Dock shelters usually have durable materials and structures that can withstand normal logistics environments and usage conditions. Its design reliability and durability can reduce maintenance costs and reduce production line downtime due to equipment failure.

Comply with safety regulations:

In some logistics industries, especially in scenarios involving dangerous goods or special goods, the use of inflatable Dock shelters can comply with safety regulations and industry standards, ensuring that goods comply with regulatory requirements during transportation and storage.

Overall, the wide application of inflatable Dock shelters in the logistics industry has played a positive role in improving efficiency, ensuring cargo safety, reducing energy consumption and maintenance costs, and contributing to the smooth operation of the modern logistics system.

Success Case: Optimizing Cold Chain Logistics

challenge:

In cold chain logistics, keeping goods transported under suitable temperature conditions is crucial to maintaining the freshness of commodities such as food. Traditional Dock shelters struggle to provide adequate sealing, resulting in temperature fluctuations and wasted energy.

solution:

Introducing high-performance inflatable Dock shelters to form a strong sealing barrier through the inflatable air chamber. This improves the isolation between trucks and cold storage, effectively reducing temperature fluctuations and energy consumption.

result:

It improves the temperature control accuracy of cold chain logistics and ensures the quality of goods.

It reduces the running time of cold storage refrigeration equipment and reduces energy consumption.

Improves the reliability of cargo transportation and reduces losses.

Successful Case: Improving Logistics Center Operational Efficiency

Challenge:

A large logistics center faces a situation where goods come in and out frequently and require efficient isolation. Traditional Dock shelters are difficult to quickly and effectively adapt to this high-intensity operating environment.

solution:

Introducing a fast-inflating Dock shelter system, which has rapid inflation and deflation functions and can achieve efficient isolation in a short time. At the same time, the system adopts intelligent control and can be seamlessly integrated with the automation system of the logistics center.

result:

It improves the efficiency of cargo circulation and reduces congestion in logistics centers.

Enhanced adaptability to trucks of different specifications and improved versatility.

Through intelligent control, remote monitoring and management of the Dock sheltering system is realized, improving the convenience of operation and management.

These cases show that in the logistics industry, the use of inflatable Dock shelters can effectively solve specific problems, improve efficiency, ensure cargo safety, and reduce operating costs. The key to successful application is to select the appropriate Dock shelter type according to actual needs and integrate it into the entire logistics system.

Inflatable Dock shelter and energy efficiency optimization

The role of inflatable Dock shelters in energy efficiency optimization

Inflatable Dock shelters play an important role in optimizing energy efficiency, especially in industrial, commercial, and logistics environments. Here are the key roles inflatable Dock shelters play in energy efficiency:

Isolated airflow and temperature control:

The inflatable Dock shelter forms an effective sealing barrier through the inflatable air chamber, which can prevent the exchange of hot and cold air and effectively isolate the internal and external environment. This is particularly important in cold chain logistics, constant temperature storage areas, and other occasions that require precise temperature control, helping to reduce energy consumption and improve the efficiency of refrigeration equipment.

Reduce energy loss:

The sealing performance of the inflatable Dock shelter can reduce energy loss, especially in situations where a constant temperature environment needs to be maintained. By preventing the leakage of hot and cold air, the energy consumption of cooling or heating equipment can be effectively reduced and energy efficiency improved.

Improve equipment operating efficiency:

By reducing the impact of the external environment on internal equipment, inflatable Dock shelters help improve the stability and efficiency of equipment operation. In industrial production lines, maintaining stable environmental conditions helps reduce equipment failure rates and improve production efficiency.

Reduce maintenance costs:

Inflatable Dock shelters are typically made from durable and easy-to-maintain materials, reducing the frequency of maintenance and replacement. Reducing downtime caused by Dock shelter failure helps improve equipment availability and reduce maintenance costs.

Adapt to different environments:

The flexibility of the inflatable Dock shelter enables it to adapt to different industrial environments, including high and low temperatures, humidity, and other conditions. Choosing the appropriate Dock shelter type based on specific environmental needs can help improve the effectiveness of energy efficiency optimization.

Improve working environment comfort:

In commercial and office spaces, inflatable Dock shelters can improve the comfort of indoor spaces. By blocking external noise, dust, and odors, it helps provide a quieter, cleaner, and more comfortable working environment, improving employee work efficiency and satisfaction.

In summary, inflatable Dock shelters provide effective solutions for enterprises and logistics environments by isolating air flow, controlling temperature, and reducing energy loss in energy efficiency optimization, helping to reduce energy consumption, improve production efficiency, and improve the environment. Comfort.

Dock shelters contribute to reducing energy consumption and environmental protection

Inflatable Dock shelters play an important role in energy efficiency optimization and environmental protection, making positive contributions to the reduction of energy consumption and environmental protection. The following is an analysis of the role of inflatable Dock shelters in these two aspects:

1. Reduction in energy consumption:

a. Improved isolation effect:

The inflatable Dock shelter forms a sealed isolation barrier through inflating, effectively preventing air, moisture, dust, and other external environmental factors from entering the storage and transportation area. This isolation effect helps reduce the operating time of cooling or heating equipment, reducing energy consumption.

b. Temperature control optimization:

In environments where specific temperatures need to be maintained, inflatable Dock shelters can effectively prevent the loss of cold or hot air and improve temperature control accuracy in cold chain logistics and storage areas. This helps reduce the work intensity of cooling or heating equipment and reduces energy consumption.

c. Reduce energy waste:

Traditional Dock shelters may have problems such as poor sealing and easy damage, resulting in a waste of energy in the process. The efficient sealing of the inflatable Dock shelter reduces the waste of energy during transportation and storage and improves the energy efficiency of the system.

d. Rapid charging and deflating technology:

Some inflatable Dock shelters adopt rapid inflation and deflation technology, which can achieve inflation and deflation in a short time. This reduces the time the Dock shelter is open and closed, helping to reduce the running time of cooling or heating equipment, thereby reducing overall energy consumption.

2. Contribution to environmental protection:

a. Reduce greenhouse gas emissions:

Reduced energy consumption leads directly to reduced greenhouse gas emissions, especially in environments that require large amounts of energy for cooling or heating. The application of inflatable Dock shelters helps mitigate the adverse effects of climate change on the environment.

b. Reduce resource waste:

The high durability and sealing performance of the inflatable Dock shelter reduce the frequency of maintenance and replacement and reduce the impact of used Dock shelters on the environment. This helps reduce resource waste and is in line with the concept of sustainable development.

c. Improve production efficiency:

By reducing operating costs, reducing losses, and improving production efficiency, the application of inflatable Dock shelters indirectly helps to reduce the excessive utilization of resources and promote the development of environmentally friendly logistics and production methods.

Overall, inflatable Dock shelters play a significant role in reducing energy consumption and environmental protection, helping to achieve more sustainable logistics, storage, and transportation management, and bringing positive impacts to both the environment and corporate operations.

Case studies on improving energy efficiency of enterprises using inflatable Dock shelters

Case: Improvement of energy efficiency of cold chain logistics enterprises

challenge:

A cold chain logistics company faces the challenges of temperature control, energy consumption, and maintaining the freshness of goods. Traditional Dock shelters fall short in sealing and speed, resulting in temperature fluctuations and wasted energy.

solution:

Introducing a high-performance inflatable Dock shelter system with rapid inflation and deflation capabilities. The inflatable Dock shelter has excellent sealing performance and can form effective isolation in a short time to avoid temperature fluctuations. In addition, the system adopts intelligent control and can be seamlessly integrated with the temperature control system of the cold chain logistics center.

result:

Improved temperature control accuracy:

The inflatable Dock shelter effectively isolates, reduces the working time of the cooling equipment, and improves the accuracy of the overall temperature control.

Reduce energy consumption:

The inflatable Dock shelter has excellent sealing performance, which effectively reduces the running time of the cooling equipment and reduces energy consumption.

Improve logistics efficiency:

The rapid inflation and deflation technology of the inflatable Dock shelter accelerates the loading and unloading process of goods, improves the overall logistics efficiency, and reduces the dwell time of trucks in the loading and unloading area.

Reduce operating costs:

Energy efficiency improvements and improved logistics efficiency combine to reduce operating costs, especially in terms of energy and labor.

This case highlights the successful application of inflatable Dock shelters in cold chain logistics, which has brought significant energy efficiency improvements and cost reductions by improving temperature control accuracy, reducing energy consumption, and improving logistics efficiency. By choosing the right door-sealing solution, companies are successfully meeting the challenges of transporting temperature-sensitive goods and achieving more sustainable and efficient operations.

Inflatable Dock shelters offer many advantages in terms of hygiene standards, especially for applications in industries such as food and pharmaceuticals. Below is a discussion and some industry standards and certification requirements:

1. Food industry application:

Hygiene requirements: In the food industry, especially in food production, processing, storage, and transportation, hygiene standards are of vital importance. The sealing performance of the inflatable Dock shelter can effectively isolate external air, dust, and impurities, helping to maintain food hygiene and quality.

Compliance standards: Some relevant hygiene standards and certificate requirements, such as ISO 22000 (food safety management system standard), HACCP (hazard analysis and critical control point standard), etc., require enterprises to take appropriate measures during production, storage, and transportation. measures to ensure health and safety.

2. Pharmaceutical industry applications:

Hygiene requirements: In the pharmaceutical industry, especially in pharmaceutical production and laboratory environments, hygiene standards are also key. Any external factors that may affect the quality and purity of the drug product need to be isolated to the greatest extent possible.

Compliance standards: Good Manufacturing Practice (GMP) is one of the international quality management system standards in the pharmaceutical industry. It requires companies to ensure the cleanliness and hygiene standards of the production environment.

3. Relevant standards and certificate requirements:

ISO 14644-1: Provides a cleanliness classification method for clean rooms and related controlled environments. Inflatable Dock shelters should meet specific class requirements in clean room environments in the pharmaceutical industry.

FDA Certification: In the United States, certification from the U.S. Food and Drug Administration (FDA) is essential for devices used in the food and pharmaceutical industries. Inflatable Dock shelters need to comply with FDA regulations in these two industries.

CE certification: European CE certification is a necessary condition for market access. It covers the hygiene and safety of products and is necessary for products sold in Europe.

success case:

A pharmaceutical company uses inflatable Dock shelters in its cleanroom production environment, complying with the cleanroom standard of ISO 14644-1. Through this upgrade, the company successfully achieved effective isolation of the clean room environment, ensuring high quality and purity of pharmaceutical production.

By following these hygiene standards and obtaining corresponding certificates, companies can ensure that the application of inflatable Dock shelters in the food and pharmaceutical industries is compliant, thereby ensuring product quality, improving hygiene standards, and also enhancing the company's reputation and market competitiveness.

The wide application of inflatable Dock shelters in many fields such as industry, logistics, food, and medicine reflects its comprehensive advantages. The following is a key summary of the comprehensive advantages of inflatable Dock shelters: excellent isolation effect, adaptability to multiple environments, improved energy efficiency and reduced energy consumption, environmentally friendly and sustainable, compliant with health standards, customized design and appearance, reduced maintenance costs, etc.

Taken together, with its excellent isolation effect, multi-environment adaptability, energy efficiency improvement, environmental sustainability, and other comprehensive advantages, inflatable Dock shelters have become an ideal choice for various industries to improve operational efficiency, reduce costs, and comply with health standards.